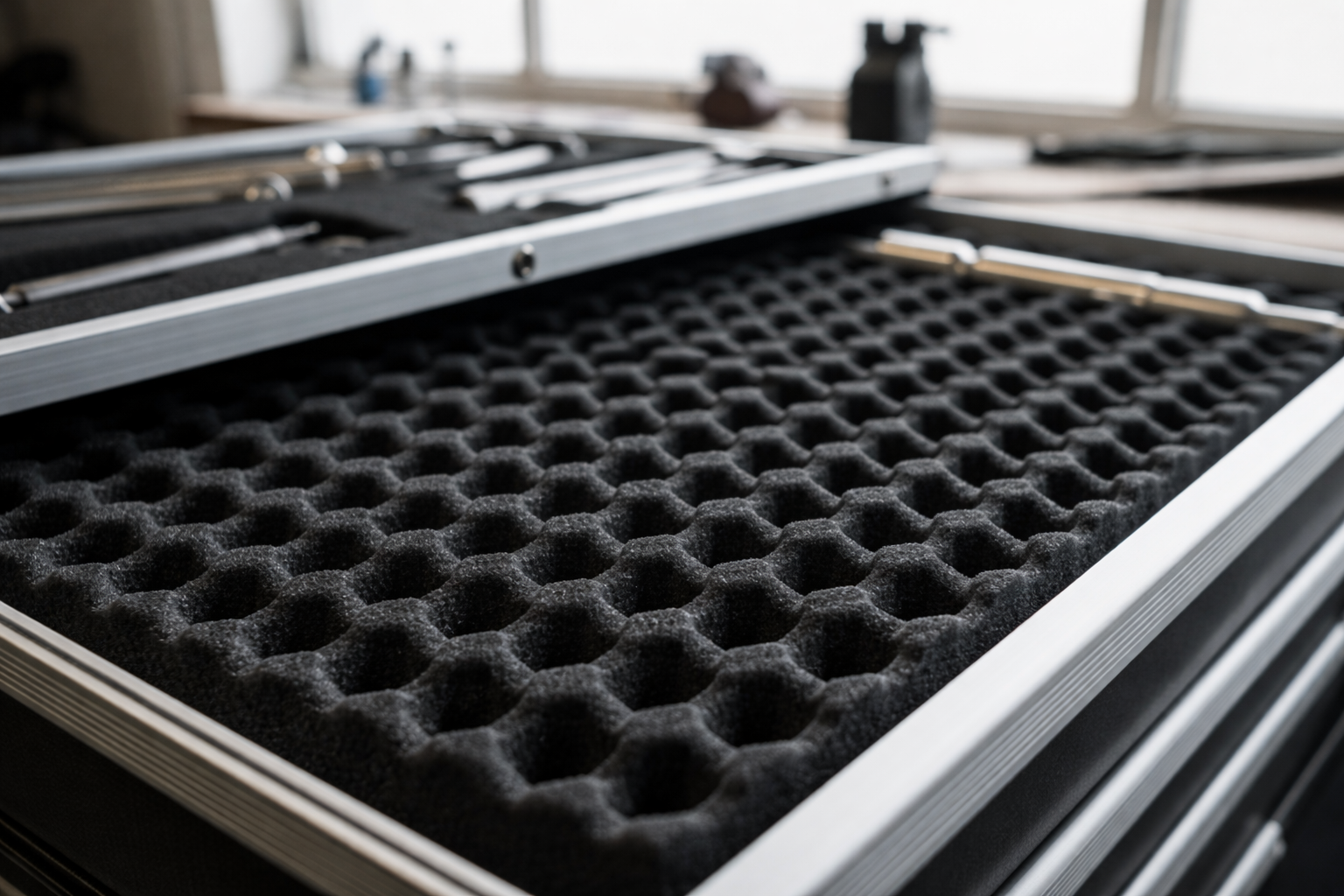

Multi-purposed Tool

Zhangs' flocking products offer a range of functional benefits, including heat and sound insulation, anti-slip properties, and effective adsorption. Additionally, they can be customized for amphiphilic molecules, making them adaptable to various applications and environments.

Learn More