The Evolution of Flock Print

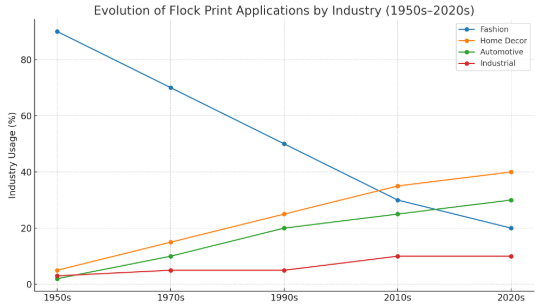

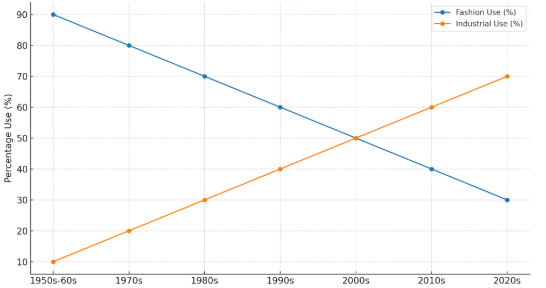

Flock printing has come a long way since its origins in the fashion industry. Once celebrated for adding texture and luxury to garments, this versatile technique has evolved into a critical surface finishing technology across multiple industries.

A Rich Textile Legacy

Flock printing began as a decorative method used primarily in apparel and home décor. Designers valued its soft velvet-like texture and ability to enhance patterns with depth and richness. From printed T-shirts to high-end wallpaper, flocking brought a unique tactile experience that elevated visual appeal.

Beyond Aesthetics: Functional Expansion

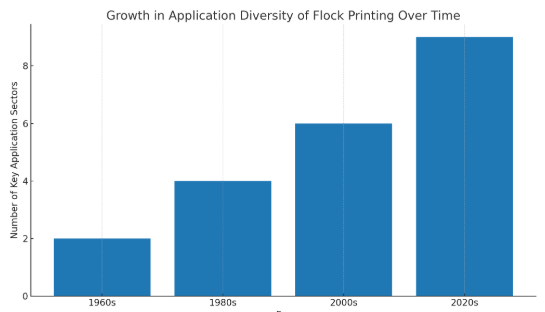

Today, flock print has moved far beyond aesthetics. In automotive manufacturing, flocking is used for dashboards, glove compartments, and seals to reduce noise and friction. In packaging, it enhances product presentation while also providing anti-slip and protective properties. Even in electronics, medical devices, and industrial tools, flocked surfaces offer insulation, grip, and dust resistance.

Why the Shift?

Advancements in adhesive chemistry, fiber technology, and electrostatic equipment have expanded the functional capabilities of flocking. Modern flock prints can be hydrophobic or hydrophilic, heat- and cold-resistant, or even electroconductive—making them ideal for diverse engineering and design challenges.

From Soft Touch to Strategic Utility

What began as a creative embellishment has matured into a smart, strategic material solution. Flock printing continues to bridge the gap between design and functionality—proving that innovation doesn't just look good, it works better too.