Understanding Basics of Electrostatic Flocking

Electrostatic flocking is a precision surface-finishing process that transforms plain substrates into plush, velvet-like surfaces by applying short fibers—called flock—onto an adhesive layer. Unlike mechanical or gravity flocking, electrostatic methods enable fibers to stand upright, creating consistent texture, increased surface area, and enhanced functionality. For companies like ZhangsFlock, delivering high quality and performance means optimizing power, field volume, and operational stability.

This article delves into the technical foundations of electrostatic flocking, including core physical mechanisms, equipment design parameters, influence of environmental factors, and quality control checkpoints.

Physical Fundamentals of Electrostatic Flocking

Coulombic Charging and Fiber Motion

Electrostatic flocking relies on charging fibers via a high-voltage field, causing them to be attracted to an adhesive-coated substrate maintained at ground or opposite polarity. This interaction is rooted in Coulomb's law: opposite charges attract, while like charges repel.

“Electrostatic flocking immobilizes electrical charges to the surface of microfibers from a high voltage-connected electrode and utilizes Coulombic forces to propel microfibers toward an adhesive-coated substrate, leaving a forest of aligned fibers.” – Source: ResearchGate, Wikipedia, P2InfoHouse

Mathematical Modeling of Fiber Motion

A scientific analysis of fiber motion shows that flocking occurs under the combined influences of electrostatic forces, aerodynamic drag, and gravity:

Newton’s Equation: m a = q E – K V – m g

where:

m = mass of fiber

q = charge

E = electric field

K V = air resistance

g = gravity

Additional models use Gauss’s law and continuity equations for field behavior. High-voltage field modeling confirms optimal charging conditions.

Experimental Validation

Studies using high-speed imaging show fibers reach 1–2 m/s under moderate voltages and up to 5–7 m/s under high-voltage fields. Relative humidity (RH) also plays a critical role—60% RH is optimal for uniform flock behavior.

Equipment Parameters and Their Impact

High-Voltage Power and Field Volume

High voltage (typically 30–100 kV) creates an effective electrostatic field volume of 0.5–1.5 m³, enabling precise coverage. Longer fibers require higher voltage to overcome inertia and align properly.

Continuous, Stable Field Generation

Fluctuating voltage creates uneven flocking. ZhangsFlock's systems stabilize power delivery, ensuring long-term process consistency.

AC vs. DC Flocking Fields

- DC systems: Provide directional flocking with steady charge.

- AC systems: Alternate polarity, improving pile density and reducing static buildup.

Environmental Influences

Relative Humidity & Fiber Conductivity

Proper humidity (~60%) improves surface conductivity of fibers and reduces static discharge, ensuring stronger charge retention and flight behavior.

Fiber Properties

| Length | Diameter | Material Conductivity |

| Long fibers require higher voltage and deliver more dramatic texture. | Influences how air drag affects trajectory. | Nylon, rayon, and modified synthetics behave differently in electrostatic environments. |

ZhangsFlock’s Technical Highlights

Power & Field Specifications

ZhangsFlock’s electrostatic field volume ranges from 0.5–1.5 m³, supporting both small and large substrates. Power capabilities ensure long fibers can be properly aligned and bonded.

Quality Metrics

- Quality Metrics

ZhangsFlock adheres to stringent quality assurance standards to ensure optimal flocking performance across diverse substrates and industries. The following key performance indicators reflect both material integrity and long-term durability of flocked products.

- Friction Fastness: ≥ Grade 4

Friction fastness evaluates the resistance of the flocked surface to abrasion and rubbing, a critical parameter for automotive, fashion, and packaging applications. ZhangsFlock ensures a Grade 4 or higher, based on standardized rubbing tests (e.g., ISO 105-X12 or AATCC TM8), indicating that the flock fibers remain securely anchored even under repeated mechanical stress.

- Conductivity and Flyability

The electrostatic behavior of fibers—particularly their ability to acquire and retain charge (conductivity) and move uniformly through the electric field (flyability)—is systematically tested. Controlled humidity conditions (typically around 60% relative humidity) are maintained during testing to simulate real production environments and to ensure stable fiber flight paths, accurate vertical alignment, and minimal fiber clumping.

- Surface Flatness

Uniform flock distribution depends on a well-balanced electrostatic field and precise adhesive application. ZhangsFlock achieves superior surface flatness through optimized electrode design, consistent power delivery, and customized spray or screen adhesive techniques. This ensures a smooth, velvety texture free from ridges, voids, or fiber clustering—especially important for visible or tactile product surfaces.

- Wash Durability

Wash durability assesses the long-term bonding strength of flock fibers under both dry and wet conditions. Through rigorous testing—including moisture exposure cycles, temperature changes, and mechanical agitation—ZhangsFlock verifies that its adhesive systems maintain fiber retention and surface integrity. This is particularly vital for textiles, decoys, and outdoor-use components subject to environmental stress.

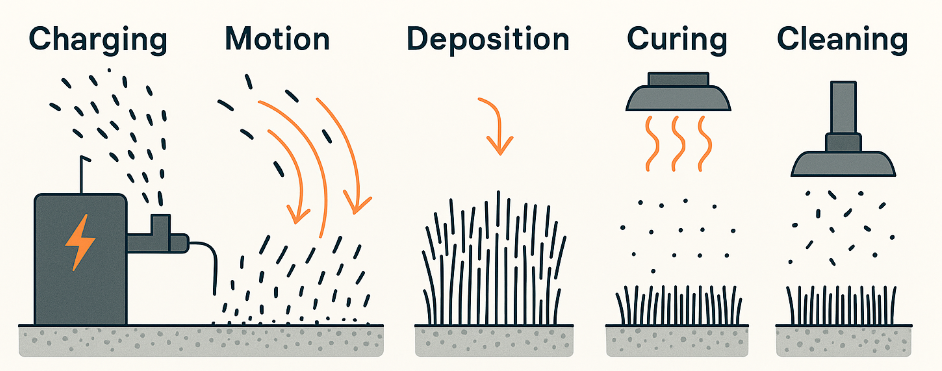

Practical Overview of Electrostatic Flocking Process

- Charging: Flock fibers are energized by a high-voltage generator.

- Motion: Fibers accelerate toward the grounded, adhesive-coated surface.

- Deposition: Fibers embed vertically due to electrostatic attraction.

- Curing: Adhesives are set via heat, UV, or air drying.

- Cleaning: Excess fibers are removed with vacuum or brushing systems.

Conclusion

Electrostatic flocking is a high-precision surface treatment method combining principles of electrostatics, fiber dynamics, and manufacturing control. From its mathematical modeling to industrial deployment, the process supports both mass production and high-value customization. With optimized high-voltage systems, humidity control, and performance metrics like ≥ Grade 4 friction fastness, ZhangsFlock stands at the forefront of electrostatic flocking innovation—delivering quality, consistency, and sustainable outcomes at scale.