Flock printing is an innovative technique that creates a velvety texture on fabrics, offering a luxurious and unique tactile experience. From fashion to automotive interiors, flock printing is used to add elegance and depth to products. This article will explain what flock printing is, the step-by-step process involved, its applications across various industries, and the technical advantages that make it a popular choice for manufacturers. If you're interested in enhancing the texture and quality of your fabrics, understanding flock printing is a must.

What is Flocking or Flock Printing?

-What is flock printing on fabric?

-What is a flock print t shirt?

What is the process of Flock print?

-Preparation of Fabric

-Application of Flocking Adhesive

-Flocking Powder Application

-Curing Process

-Finishing Touches

Application and trend of Flocking print

-Application of flocking fabrics in clothing

-Flocking coating used in automotive interiors

-Flocking powde for home textile product decoration

The Technical Edge of Flock Printing

Frequently Asked Questions(FAQ)

-Which type of printing is best on fabric?

-What type of t-shirt printing lasts the longest?

-How to stop t-shirt print from peeling?

Conclusion

What is Flocking or Flock Printing?

What is Flock Printing on Fabric?

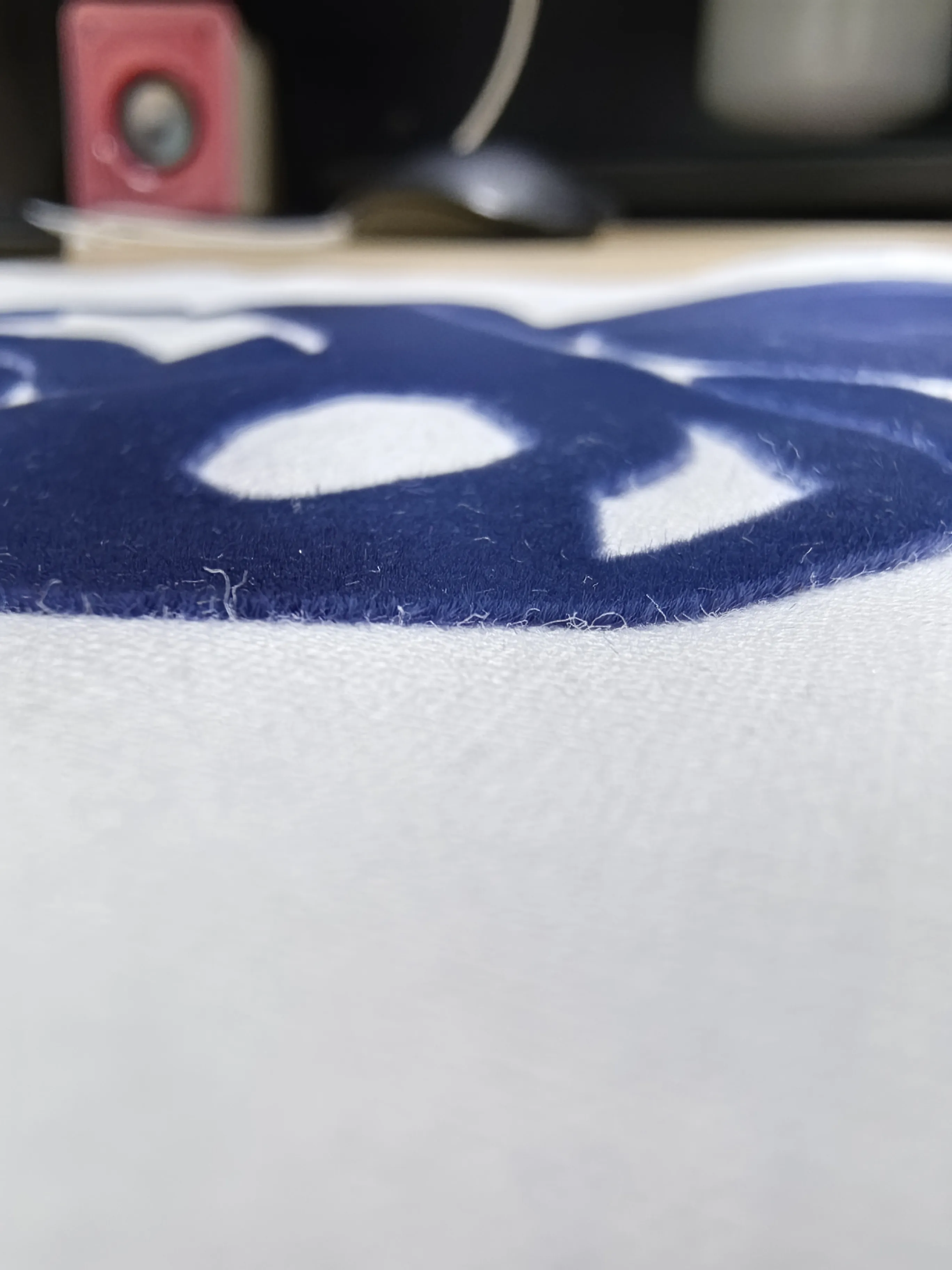

Flock printing is a specialized printing technique that involves the application of tiny, short fibers (called "flock") onto a fabric to create a raised, velvet-like texture. The fibers are typically made from materials like polyester, nylon, or rayon and are applied to the fabric using an adhesive.

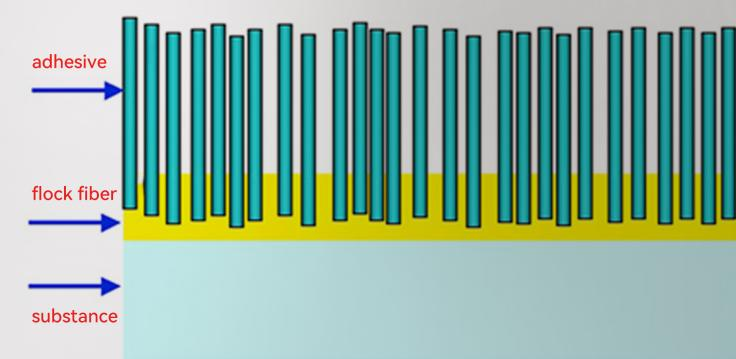

In this process, the fabric is coated with a special adhesive, and then the flocking fibers are deposited onto the adhesive. These fibers are electrostatically charged and align themselves upright, creating a soft, velvety finish. The result is a textured design that feels luxurious to the touch while adding depth and dimension to the fabric's surface.

Flock printing is highly popular in fashion and home decor because it offers an elegant, rich appearance that standard printing methods can't replicate. It’s often used for making t-shirts, dresses, upholstery fabrics, and even automotive components.

What is a Flock Print T-shirt?

A flock print t-shirt is a t-shirt that has a design created using the flock printing technique. The design on the shirt has a raised, velvety texture, adding a tactile dimension to the printed graphic. Flock printing on t-shirts is especially popular in fashion, where soft, luxury-feeling prints are desired. The tactile quality of a flocked design makes it stand out from standard printed t-shirts, giving it a high-end look and feel.

Unlike other types of printing, which use flat inks, flock printing creates a distinct texture that can be felt when touched. This technique is commonly used for custom-made shirts, sports apparel, and limited-edition fashion lines to make the garments feel and look more premium.

What is the Process of Flock Print?

Flock printing involves a multi-step process that requires precision and attention to detail. The main stages include fabric preparation, adhesive application, flocking powder application, curing, and finishing touches.

Preparation of Fabric

The first step in the flock printing process is the preparation of the fabric. The fabric is cleaned and treated to ensure that the flocking adhesive adheres properly. This may involve pre-washing to remove any oils or contaminants and sometimes applying a base layer of adhesive or primer to improve the bonding process.

The fabric is then laid flat, ready to receive the adhesive and flocking powder.

Application of Flocking Adhesive

The next step is to apply the flocking adhesive to the fabric. The adhesive is usually applied in a pre-determined design or pattern, either by screen printing, roller printing, or spraying. The adhesive serves as the base where the flocking fibers will attach. It’s important that the adhesive is applied evenly and accurately to ensure that the flocking fibers adhere properly.

Flocking Powder Application

After the adhesive is applied, the flocking powder (small, fine synthetic fibers) is applied to the adhesive. This is done using an electrostatic process, where the fibers are charged and then attracted to the adhesive, standing upright to create the desired texture. The fibers can be applied in a variety of colors and lengths to achieve different effects, such as a dense, plush look or a more subtle velvet-like finish.

Curing Process

Once the flocking powder is applied, the fabric undergoes a curing process, which involves heating it to activate and bond the adhesive. This step ensures that the flocking fibers stay securely attached to the fabric, creating a durable and long-lasting texture. The fabric is usually passed through an oven or heat press for this process.

Finishing Touches

Once the fabric is cured, the final step is to remove any excess flocking powder and give the fabric a clean, smooth appearance. This may involve brushing off the surface to remove stray fibers and ensure the design is crisp and precise. Afterward, the fabric is ready for further finishing processes like cutting, sewing, or dyeing, depending on its intended use.

Applications and Trends of Flocking print

Application of Flocking Fabrics in Clothing

Flock printing is commonly used in fashion to create luxurious textures on a variety of garments. It’s especially popular for t-shirts, jackets, scarves, and even socks, where designers want to add depth and a soft feel to the fabric. Flock prints are often used for creating logos, graphic designs, and intricate patterns on clothing. These prints not only enhance the visual appeal but also create a unique tactile experience, making the fabric feel more premium.

Flocked garments are usually more expensive due to the high-quality finish they offer. These products are often sold as limited-edition items or as part of high-end fashion collections.

Flocking Coating Used in Automotive Interiors

Flock printing is also extensively used in the automotive industry. It’s applied to car interior components like dashboards, door panels, and trim parts. The flocking coating creates a soft, suede-like texture that enhances the visual appeal of the car's interior. It also helps to reduce glare, making it a practical solution for areas exposed to sunlight.

Additionally, flocked materials in automotive interiors can reduce noise and provide a more comfortable, aesthetically pleasing feel. This use of flocking adds both functional and decorative value to car interiors.

Flocking Powder for Home Textile Product Decoration

In home décor, flock printing is increasingly used on textiles like curtains, upholstery, and cushions. The flocked fabric creates an elegant and luxurious feel in any home, adding texture and depth to ordinary pieces. Flocked curtains or cushions, for example, give off a rich, sophisticated vibe, elevating the overall design of the room.

Flocking powder can also be used for creating intricate, detailed designs on fabric, such as floral patterns or geometric shapes. It’s a versatile technique that offers endless possibilities for customizing home textiles.

The Technical Edge of Flock Printing

Flock printing stands out from other printing techniques because of the unique, tactile quality it imparts to fabrics. Some of the key technical advantages include:

1.Texture and Depth

Unlike flat prints, flock printing creates a raised texture that adds depth and dimension to the design. The fibers stand upright on the fabric, giving it a soft, velvety feel that is both visually appealing and pleasant to the touch.

2.Durability

Flock prints are long-lasting and resistant to wear and tear. The flocked fibers are securely bonded to the fabric, ensuring that the design doesn’t fade or peel with time. This makes it ideal for high-quality, durable products.

3.Versatility

Flock printing can be applied to a wide range of materials, including cotton, polyester, and even synthetic fabrics. This makes it suitable for a variety of applications across industries, from fashion to automotive and home décor.

4.Unique Aesthetic Appeal

Flock printing offers a unique aesthetic that can’t be replicated with standard printing methods. The plush finish and tactile nature of flocked fabrics make them highly desirable in the market, adding a touch of luxury and sophistication to any product.

Frequently Asked Questions (FAQ)

Which Type of Printing Is Best on Fabric?

The best type of printing depends on the intended outcome. Screen printing is ideal for vibrant, long-lasting designs, while digital printing works well for detailed, multi-colored graphics. Flock printing stands out for its unique texture, offering a luxurious, velvet-like finish.

What Type of T-shirt Printing Lasts the Longest?

Screen printing and flock printing are both known for their durability. These methods provide long-lasting prints that are resistant to fading, cracking, or peeling, making them suitable for high-quality t-shirt printing.

How to Stop T-shirt Print from Peeling?

To prevent peeling of prints, whether flocked or screen-printed, it’s important to follow proper care instructions. Wash the t-shirt inside out in cold water, and avoid using a tumble dryer. Iron the garment inside out or at a low temperature to preserve the print.

Conclusion

Flock printing offers a unique way to enhance the texture and appearance of fabrics. Its velvety finish and luxurious feel make it ideal for high-end fashion, automotive interiors, and home textiles. With its durability, versatility, and aesthetic appeal, flock printing is a technique that continues to grow in popularity across various industries. Whether you’re looking to elevate your clothing designs or add sophistication to your home décor, Zhangs flock printing provides an excellent solution.