Electrostatic flocking equipment plays a significant role in various industries, particularly in fields requiring high quality and efficient production. As technology continues to evolve, electrostatic flocking has been widely applied in textiles, automotive, medical, and many other industries, becoming an important method for enhancing the appearance and functionality of products. This article will provide a detailed introduction to the working principle, production process, unique advantages, and practical applications of electrostatic flocking systems.

Introduction to Electrostatic Flocking

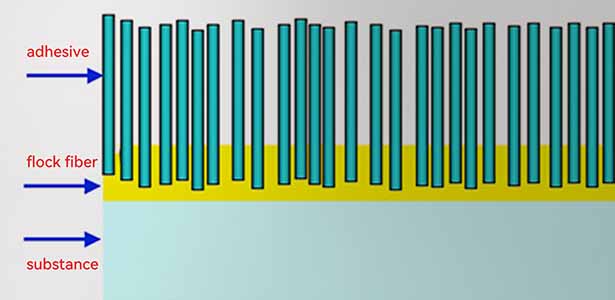

Electrostatic flocking is a process in which fine fibers are uniformly attracted to the surface of a substrate using electrostatic forces, creating a velvet-like effect. This process not only enhances the aesthetic appearance of materials but also imparts specific physical properties to them. To fully understand electrostatic flocking technology, it is necessary to first grasp the basic concepts and materials involved.

Flocking Fibers

Flocking fibers are materials that are fixed onto the surface of a substrate using electrostatic forces, creating a layer of fibers. Common flocking fibers include cotton, rayon, acrylic, nylon, and polyester. The choice of fiber material affects the flocking result and the tactile properties of the product. For example, cotton fibers provide a natural soft feel, suitable for high-end textiles, while nylon fibers are known for their durability and are often used in products that require high wear resistance.

The tactile feel of the flocked product is closely related to the thickness of the fibers, the cutting method, and the depth of the flocking. Precisely cut fibers can form a uniform and specific depth of the flocked layer, resulting in a smoother touch and more attractive appearance. With advancements in technology, the cutting process and material selection for flocking fibers have become more precise and diverse, meeting the needs of different industries.

Electrostatic flocking is a method in which fibers are vertically attracted to the surface of a substrate using electrostatic forces. Unlike traditional flocking methods, electrostatic flocking does not require mechanical force; instead, it relies on electrostatic principles to attach fine fibers to a pre-treated surface. This method not only improves the uniformity of the flocking but also enhances the adhesive strength of the fibers, preventing them from shedding easily.

Electrostatic flocking equipment typically produces thin sheets, but due to the unique process, the flocking effect is very uniform and visually appealing. The fibers are evenly spaced, and the final product has a smooth, delicate surface with strong visual and tactile effects.

Electrostatic Flocking Machine

An electrostatic flocking machine is a device specifically designed for the electrostatic flocking process. It primarily uses an electric field to evenly attach fine flocking fibers to the substrate surface. Electrostatic flocking systems typically include multiple functional modules, such as fiber feeding systems, electrostatic generators, and adjustment devices, to ensure uniform flocking and secure fiber attachment.

Electrostatic flocking machines are widely used in various industries, including textiles, automotive, medical, and decorative products. By finely adjusting factors like voltage, electric field strength, and temperature, electrostatic flocking machines provide more stable and reliable flocking results.

The Production Process of Electrostatic Flocking

The electrostatic flocking process involves several steps, each requiring careful operation and control to ensure the quality of the final product.

Adhesion

The first step in the process is preparing the substrate surface with an adhesive treatment. This can be done by applying glue or spraying adhesive to form a layer of bonding agent that enhances the adhesion between the fibers and the substrate. The choice of adhesive is crucial as it directly impacts the stability and durability of the flocking effect.

Flocking

Flocking is the core step of the electrostatic flocking process. A high-voltage electric field is generated by the electrostatic generator, which causes the fibers to be attracted to the substrate surface and form a uniform layer of fibers. At this stage, operators must adjust the voltage and temperature settings of the electrostatic generator according to the specific requirements to ensure that the fibers are evenly and securely attached.

Drying

The drying step is essential to ensure that the flocking remains firmly fixed to the substrate and does not shed easily. The adhesive’s moisture content is rapidly evaporated using heating or infrared drying equipment, ensuring that the fibers stay securely attached. The control of temperature and time during this process is crucial to avoid over-drying, which may cause fiber shedding.

Dust Removal

During the flocking process, dust and small fiber fragments are produced. These impurities need to be removed in a timely manner using dust removal equipment to ensure that the product surface remains clean and of high quality.

Unique Advantages of Using an Electrostatic Flocking Machine

Compared to traditional flocking systems, Zhangs electrostatic flocking machine offers several unique advantages. Its high production efficiency and excellent electrostatic performance make it the preferred choice for many industries.

Excellent Electrostatic Performance

Zhangs electrostatic flocking machine uses advanced electrostatic generation technology, which can quickly generate a strong electric field to ensure that the flocking fibers are uniformly and securely attached. Compared to traditional flocking equipment, electrostatic flocking systems have more stable electrostatic performance, reducing issues such as uneven flocking caused by unstable electrostatic fields.

High Color Fastness

Zhangs electrostatic flocking materials have a washing color fastness rating of level 4, meaning that the color remains highly stable after washing and will not fade over time. This makes products produced with Zhangs electrostatic flocking machines more durable, particularly suitable for high-demand textiles and home products.

Multi-Purpose Tool

Zhangs electrostatic flocking machine is versatile and can be used in a variety of fields, including textile processing, automotive, medical, and home products. It offers a range of functional advantages, such as heat insulation, soundproofing, anti-slip properties, and effective adhesion. The system can also be customized according to specific customer needs, meeting the unique requirements of different products.

Smooth Surface

Electrostatic flocking equipment ensures that the flocking is uniformly distributed, resulting in a smooth, delicate surface with a comfortable tactile feel. The fibers are evenly spaced, without the unevenness or graininess often found in traditional flocking methods, making the final product look more refined and stylish.

Applications of Electrostatic Flocking Machines

Electrostatic flocking machines are widely used across various industries. Below are some typical applications:

Medical Supplies

In the medical industry, electrostatic flocking technology is commonly used for the surface treatment of medical tubes, surgical instruments, and other equipment. Flocking enhances the comfort of the equipment, prevents surface scratching, and makes operations smoother.

Automotive

Electrostatic flocking is widely applied in the automotive industry, particularly for manufacturing car interiors. Electrostatic flocking can be used on car interior parts such as dashboards, door panels, and other components to improve their aesthetics, tactile feel, and anti-slip performance.

Christmas Decorations

Christmas trees, ornaments, and other decorations often use electrostatic flocking to simulate snow, enhancing the festive atmosphere. Flocking makes these decorations appear more vivid and realistic.

Latex Gloves

In the production of latex gloves, electrostatic flocking technology is used to improve the wearing experience. Gloves treated with flocking have a smoother interior surface, making them less sticky and easier to put on and take off.

The electrostatic flocking machine, as an innovative surface treatment device, has demonstrated tremendous application potential across various industries. Whether in terms of production efficiency, flocking results, or the functionality of the product, the electrostatic flocking equipment offers significant advantages. Zhangs electrostatic flocking machine, with its high efficiency, precision, and multifunctional capabilities, has become one of the leading flocking systems on the market.

As electrostatic flocking technology continues to evolve, it will play an increasingly important role in more industries. Whether enhancing the appearance of products or improving their physical properties, electrostatic flocking machines provide innovative and efficient solutions for modern manufacturing.