Flock printing, as a unique printing technology with both visual and tactile appeal, has gained increasing attention in the fashion, home decoration, and industrial sectors in recent years. Due to its exquisite tactile effect and three-dimensional visual attraction, flock printing has become a favorite among many designers and manufacturers. This article will delve into the definition, working principles, broad applications, and technical advantages of flock printing, while also exploring how innovation can enhance the effectiveness of this process. Finally, we will highlight the unique position of Zhangs Flock Printing in the market.

What is Flock Printing?

Flock printing is a process where tiny fibers (referred to as flock) are uniformly attached to the surface of a printed substrate, creating unique textures and color effects. Originating in the 1950s, flock printing has developed over the decades into a widely used decorative printing technique in fields such as fashion, and advertising materials.

Compared to traditional printing methods, the key feature of flock printing lies in its ability to provide a surface with rich layers and a distinctive tactile effect. This not only makes the printed patterns more visually striking but also imparts a soft and delicate feel to the surface. With this technique, designers can create unique works that combine artistic value with practical benefits, giving products higher market appeal and aesthetic value.

How Does Flock Printing Work?

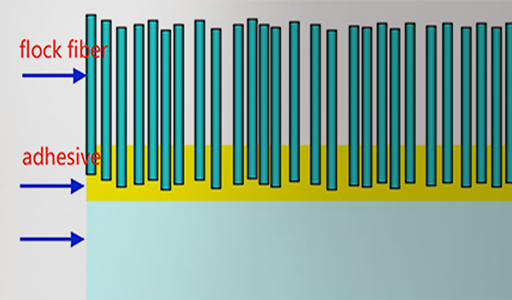

Flock printing works by applying static electricity to attach flock fibers to a substrate that has been coated with adhesive. The process typically involves the following steps:

Substrate Preparation

First, the surface of the substrate must be treated to ensure the adhesive can be evenly applied. Substrates can include various materials such as textiles, paper, plastics, and metals.

Applying Adhesive

A special adhesive is then applied to the substrate surface. The type of adhesive used varies depending on the nature of the substrate and the desired effect, with options including water-based, oil-based, or solvent-based adhesives.

Sprinkling Flock Fibers

Flock fibers are applied to the adhesive-coated surface using static electricity. The static force ensures that the fibers attach evenly and firmly to the adhesive, forming a plush texture.

Heat Treatment and Curing

To ensure that the flock fibers are securely attached to the substrate, heat treatment or curing is usually required. This step solidifies the adhesive and bonds the fibers permanently, ensuring long-lasting durability.

Through these processes, the final product presents unique colors and textures, while maintaining an excellent tactile experience.

Broad Applications of Flock Printing

Flock printing not only offers impressive visual effects but also boasts outstanding physical properties, making it widely applicable across various industries. Below are three examples of different flock printing applications:

Flock Coating

Flock coating technology involves evenly applying flock fibers to the surface of a substrate, forming a soft, plush layer. This technique is commonly used in automotive interiors, and wall decorations. Flock coatings enhance the tactile quality of products and increase their durability and resistance to aging. For example, many high-end automotive seats and interior components use flock coating to provide a luxurious and comfortable driving experience.

Flock Screen Printing

Flock screen printing combines traditional screen printing with flocking technology. By using a screen to precisely apply adhesive to specific areas, and then applying static electricity to attach the flock fibers, this method is widely used in fashion industries such as clothing, footwear, and bags. It allows for high-precision and complex flocked patterns, elevating the visual and tactile appeal of the products.

Custom Flock Printing

Custom flock printing opens up a world of possibilities for personalized designs. With customized designs and flocking technology, users can apply their own artwork, brand logos, or other distinctive patterns to various products. For example, custom flocked patterns in home décor can bring unique aesthetic effects to living spaces, while in brand marketing, flock printing can help present a brand’s image in a more memorable and personalized way.

Technical Advantages of Flock Printing

Compared to traditional flexographic printing, flock printing offers several notable technical advantages, which make it stand out in many industries:

Smooth Surface

Flock printing provides a smooth and even surface, avoiding common issues such as uneven ink or overflow seen in traditional printing. Additionally, the delicate surface formed by the flock fibers not only offers a visually pleasing appearance but also provides an excellent tactile experience, making it more appealing in high-end markets.

Excellent Electrostatic Properties

Flock printing utilizes static electricity to securely attach the fibers to the substrate, which enhances the product's dust-resistant and dirt-repellent properties. In high-end electronics and home goods, flock printing's electrostatic protection can effectively prevent static electricity from damaging the products.

High Color Fastness

Zhangs flocking materials have a wash color fastness rating of 4, meaning that the printed patterns are highly durable and maintain their vivid color even after multiple washes. This characteristic is especially important in the fashion industry, where consumers have high expectations for the color and durability of clothing and home accessories. Flock printing easily meets these requirements.

Versatile functionality

Flock printing not only provides aesthetic effects in terms of visual appeal and tactile sensations, but also offers several practical features. For instance, flock materials possess excellent thermal and sound insulation properties, making them valuable in specific industrial applications. Additionally, the anti-slip and strong adhesion properties of flocking make it ideal for use in footwear, carpets, and other products.

Flock printing is not only a traditional craft with a rich history but also a modern technology filled with creativity and innovation. Through its unique visual effects, tactile qualities, and physical properties, flock printing adds significant artistic and functional value to a wide range of products. From fashion to industrial applications, flock printing showcases its vast potential.

As an industry leader,Zhangs Flock Printing has secured a prominent position in both domestic and international markets through continuous technological innovation and craftsmanship. Whether it’s flock coating, screen printing, or custom flock printing, Zhags Flock Printing demonstrates superior quality and results. If you are looking for a technology that can enhance the appearance and functionality of your products, flock printing is undoubtedly a choice worth considering.

Recommended reading

1.What is flock printing and How to apply it?