Flocked fabric has become an essential material in modern clothing design, offering a distinctive texture, visual depth, and premium feel. From fashion apparel and sportswear to branding applications such as flocked logos, clothing flocking is widely used to enhance both aesthetics and functionality. This complete guide explains what flocked fabric is, how flocked cloth is used in clothing, the clothing flocking process, key application scenarios, and how to choose reliable flocking fabric manufacturers for long-term production success.

What is flocked fabric?

-What does flocked fabric mean?

-What does flocked mean in clothing?

-Difference between fabric flock and traditional textile finishes

What is flocked cloth and how is it used in clothing?

-What is flocked cloth?

-What is flocked cloth good for?

Clothing flocking process explained

-Fiber preparation for flocking clothing material

-Adhesive application in clothing flocking

-Electrostatic flocking for fabric flock

Popular applications of flocking fabric in clothing

-Flocking jersey for sportswear and fashion

-Flock t shirt design and manufacturing

-Flocking logo for branding and decoration

How to choose reliable flocking fabric manufacturers

-Manufacturing capacity for flocked fabric

-Quality assurance and certifications

-Support for apparel brands and garment factories

What Is Flocked Fabric?

What Does Flocked Fabric Mean?

Flocked fabric refers to a textile material that has a layer of short fibers—known as flock fibers—applied to its surface using an adhesive and a controlled flocking process. These fibers are fixed upright, creating a soft, velvety, or suede-like finish. Unlike woven or knitted textures formed during fabric construction, flocked fabric gains its surface characteristics through a secondary finishing process.

The flocking fabric process allows manufacturers to precisely control fiber length, density, and alignment, resulting in consistent surface quality. Because of this, flocked fabric is widely used in clothing applications where tactile appeal and visual richness are important.

What Does Flocked Mean in Clothing?

In clothing, “flocked” describes garments or fabric surfaces that feature raised fibers bonded to the base fabric. Flocked clothing is valued for its soft hand feel, enhanced comfort, and premium appearance. Common examples include flock T-shirts, flocking jerseys, and garments with flocking logos.

From a design perspective, flocked fabric adds dimension and contrast to clothing, making it ideal for statement pieces, sportswear graphics, and brand identification. Functionally, flocked surfaces can also improve grip, warmth, and wear comfort in specific applications.

Difference Between Fabric Flock and Traditional Textile Finishes

Fabric flock differs significantly from traditional textile finishes such as printing, coating, or embroidery. While printed designs remain flat and embroidery relies on stitched threads, flock fabric introduces a three-dimensional fiber layer. This provides a richer texture and more durable visual effect.

Compared to coatings, flocked fabric remains breathable and flexible, making it more suitable for clothing applications. These advantages explain why fabric flock is increasingly favored in both fashion and functional apparel.

What Is Flocked Cloth and How Is It Used in Clothing?

What Is Flocked Cloth?

Flocked cloth is a finished textile in which flock fibers are permanently bonded to a fabric substrate. The base fabric may be cotton, polyester, nylon, or blended materials, depending on the intended use. Through electrostatic flocking, fibers are aligned vertically, ensuring uniform coverage and long-term durability.

Flocked cloth can be produced as full-surface material or customized with patterns, logos, and localized designs. This versatility makes flocked cloth a preferred option for garment manufacturers seeking differentiation.

What Is Flocked Cloth Good For?

Flocked cloth is widely used in clothing applications that require both visual appeal and functional performance. In fashion garments, flocked fabric delivers a luxurious look and feel. In sportswear, flocking jerseys benefit from improved texture and high-contrast graphics.

Flocked cloth is also ideal for branding, as flocking logos offer superior durability compared to printed alternatives. The raised texture enhances brand visibility while maintaining softness and comfort for the wearer.

Clothing Flocking Process Explained

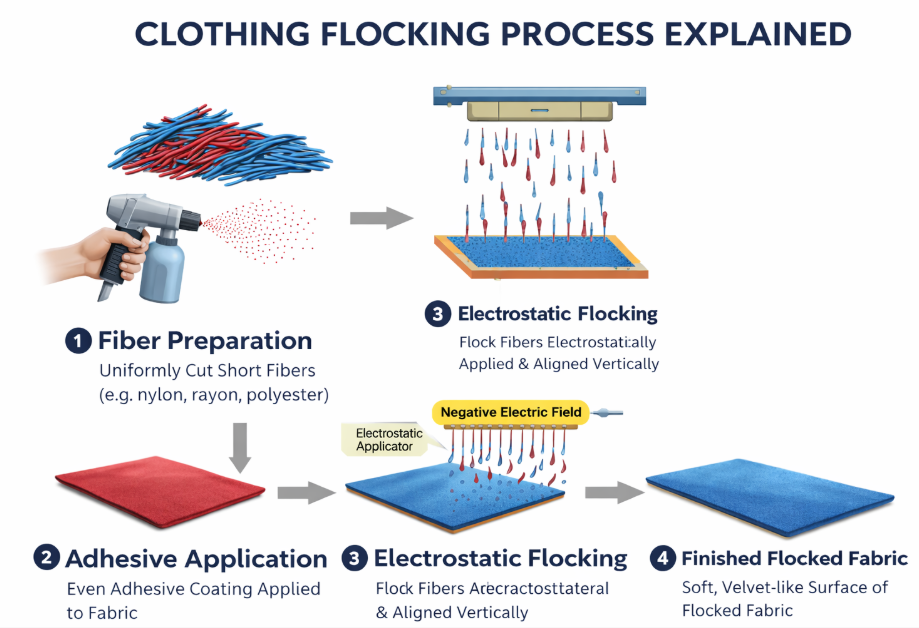

Fiber Preparation for Flocking Clothing Material

The quality of flocking clothing material begins with fiber preparation. Flock fibers—commonly nylon, rayon, or polyester—are precisely cut to uniform lengths. Fiber length consistency directly affects surface smoothness, durability, and visual uniformity.

Professional flocking fabric manufacturers carefully select fiber materials based on clothing requirements such as softness, abrasion resistance, and wash durability. Proper fiber preparation ensures stable performance throughout the garment’s lifecycle.

Adhesive Application in Clothing Flocking

Adhesive application is a critical step in clothing flocking. The adhesive must securely bond flock fibers to the fabric while remaining flexible and washable. Adhesive selection varies depending on fabric type, fiber material, and end-use requirements.

Uniform adhesive distribution ensures consistent fiber density and prevents shedding. Advanced manufacturers optimize adhesive formulations to balance bonding strength with garment comfort.

Electrostatic Flocking for Fabric Flock

Electrostatic flocking is the most widely used method in fabric flock production. During this process, an electric field causes flock fibers to stand upright as they embed into the adhesive-coated fabric. This vertical alignment produces the characteristic velvet-like texture associated with high-quality flocked fabric.

Electrostatic flocking ensures precise fiber placement, excellent adhesion, and long-term durability. It is particularly suitable for clothing applications requiring fine detail, such as flocking logos and patterned flock T-shirts.

Popular Applications of Flocking Fabric in Clothing

Flocking Jersey for Sportswear and Fashion

Flocking jersey applications are common in sportswear, team uniforms, and athletic fashion. Flocked numbers, names, and graphics provide strong visual contrast and superior wear resistance. Unlike printed graphics, flocked designs maintain clarity after repeated washing and use.

In fashion, flocking jerseys are also used to create bold textures and premium finishes, enhancing garment value and brand perception.

Flock T Shirt Design and Manufacturing

Flock T-shirt production is a popular use of clothing flocking technology. Flocked designs offer a soft, raised texture that stands out visually and tactually. Compared to flat printing, flock T-shirts feel more luxurious and durable.

Manufacturers can customize flock patterns, colors, and densities to meet branding and fashion requirements. This flexibility makes flock T-shirts suitable for promotional wear, retail collections, and premium casual clothing.

Flocking Logo for Branding and Decoration

Flocking logos are widely used for apparel branding due to their durability and tactile appeal. The raised fiber surface adds depth to logos, improving brand recognition and perceived quality.

Flocking logos are commonly found on jackets, hoodies, uniforms, and sportswear. Their resistance to wear and washing makes them a long-lasting branding solution for apparel brands.

How to Choose Reliable Flocking Fabric Manufacturers

Manufacturing Capacity for Flocked Fabric

Reliable flocking fabric manufacturers must have sufficient production capacity to meet consistent quality and delivery requirements. This includes advanced flocking equipment, stable fiber supply, and experienced technical teams.

Manufacturers capable of handling both large-scale production and customized flocked fabric solutions are better positioned to support apparel brands with diverse needs.

Quality Assurance and Certifications

Quality control is essential in flocked fabric manufacturing. Reputable manufacturers implement strict testing procedures for fiber adhesion, color fastness, abrasion resistance, and wash durability.

Certifications and standardized quality systems demonstrate a manufacturer’s commitment to consistent performance. Choosing a supplier with proven quality assurance processes reduces production risk and ensures reliable clothing flocking results.

Support for Apparel Brands and Garment Factories

Beyond manufacturing, strong technical and service support is a key factor when selecting flocking fabric manufacturers. This includes material selection guidance, process optimization, and after-sales support.

Manufacturers who understand apparel production requirements can provide tailored flocking clothing material solutions, helping garment factories and brands achieve better efficiency and product performance.

Conclusion

Flocked fabric plays a vital role in modern clothing design, offering unique texture, durability, and branding advantages. From flocked cloth used in fashion garments to flocking jerseys, flock T-shirts, and flocking logos, clothing flocking continues to expand across the apparel industry.

Understanding the flocking fabric process and working with reliable flocking fabric manufacturers are essential steps toward producing high-quality flocked clothing. With the right materials, technology, and manufacturing partners, flocked fabric can significantly enhance both the aesthetic and functional value of clothing products.