Flocking technology has become an essential surface treatment across textiles, apparel, automotive, packaging, and industrial products. Compared with solid materials such as plastic, metal, and rubber, flocked materials offer superior tactile comfort, thermal performance, safety, and aesthetic value. This article explores the meaning of flock material, the fundamentals of electrostatic flocking, and the functional advantages of flocked materials in both industrial and consumer applications, while highlighting how Zhangs Flocking Materials delivers reliable, high-quality flocking solutions worldwide.

-Flock Material Meaning and the Basics of Electrostatic Flocking

What is flock material in textile?

How does electrostatic flocking work?

Why flocking material is widely used in industrial and consumer applications?

-Flocked material vs Solid materials: Why flocking is better

Soft touch advantage of flocked fabric

Thermal comfort and warm touch in flocking clothing material

Premium design value using black velour flocking material

-Functional Benefits of Flocked Material in Industrial Use

Heat Insulation Performance of Flocked Material on Metal Products

Safety Protection with Nylon Flocking Material

Noise Reduction Using Flocked Material in Automotive Interiors

-Performance advantages of flocking in apparel and daily products

Moisture absorption in flocking clothes

Anti-slip performance with flocked material

Waterproof solutions with reverse flocked fabric

-Types of flocking materials and their applications

Choosing the best flocking materials for different needs

Flock material for printing and decorative surfaces

Seasonal and decorative uses of christmas tree flocking material

Conclusion

Flock Material Meaning and the Basics of Electrostatic Flocking

What Is Flock Material in Textile?

Flock material refers to a surface material created by applying millions of short fibers—called flock—onto a substrate using an adhesive layer. In textile applications, flock material transforms flat fabrics into soft, velvety surfaces with enhanced tactile and visual appeal. Unlike traditional woven or knitted fabrics, flocked fabric achieves its texture through fiber orientation rather than yarn structure.

In textiles, flock material is commonly used for clothing labels, decorative panels, fashion garments, and functional apparel. The resulting flocked surface feels plush, skin-friendly, and warm, making it particularly suitable for applications where comfort and sensory experience matter.

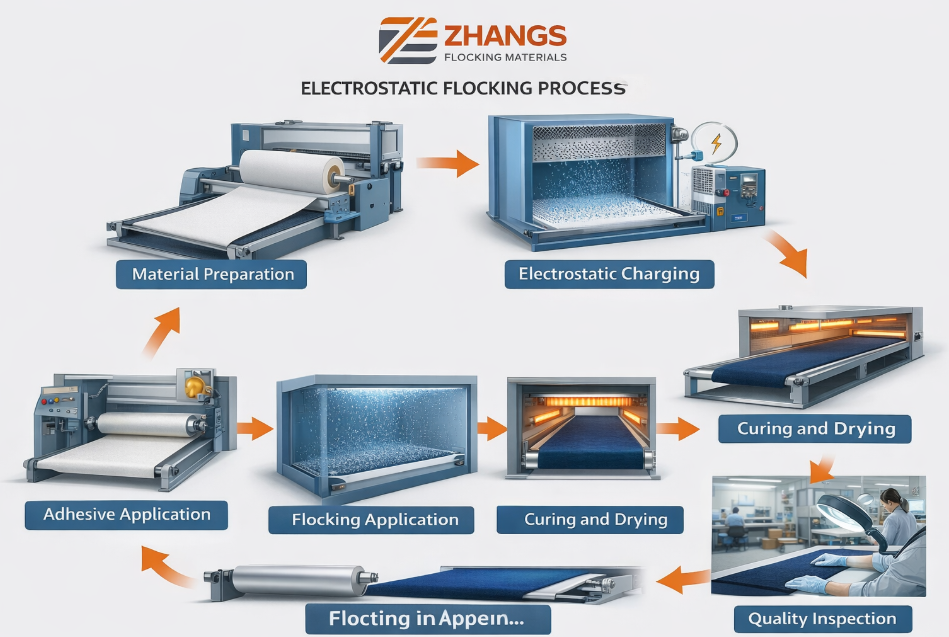

How Does Electrostatic Flocking Work?

Electrostatic flocking is the most widely used flocking process due to its precision and consistency. During this process, short fibers—often nylon or rayon—are electrically charged and projected vertically onto an adhesive-coated surface. The electric field ensures that fibers stand upright, creating a dense and uniform flock layer.

This controlled orientation is what gives flocked material its signature softness, durability, and professional finish. Electrostatic flocking can be applied to textiles, plastics, metals, glass, paper, and composites, making it one of the most versatile surface treatment technologies available.

Why Is Flocking Material Widely Used in Industrial and Consumer Applications?

Flocking material bridges the gap between function and aesthetics. It enhances product performance while also improving visual quality and user experience. From industrial safety solutions to premium consumer packaging, flocking delivers benefits that solid materials alone cannot provide. Its adaptability, scalability, and compatibility with different substrates make it a preferred choice across industries.

Flocked Material vs Solid Materials: Why Flocking Is Better

Soft Touch Advantage of Flocked Fabric

Compared with plastic, metal, or rubber surfaces, flocked fabric offers a distinctly soft and luxurious hand feel. The velvety texture reduces skin irritation and enhances comfort, especially in products that come into frequent contact with the human body.

This soft-touch advantage makes flocked material ideal for apparel, accessories, packaging interiors, and lifestyle products. Unlike cold, rigid solid materials, flocked fabric creates a warm and inviting user experience that immediately communicates quality.

Thermal Comfort and Warm Touch in Flocking Clothing Material

One of the most noticeable benefits of flocking clothing material is thermal comfort. In cold environments, solid materials like metal or plastic can feel uncomfortably cold against the skin. Flocked surfaces, however, retain warmth and feel gentle on contact.

This property is especially valuable for clothing labels, inner linings, and winter apparel. Flocking clothes designed with comfort in mind help reduce discomfort caused by temperature differences, improving wearability and customer satisfaction.

Premium Design Value Using Black Velour Flocking Material

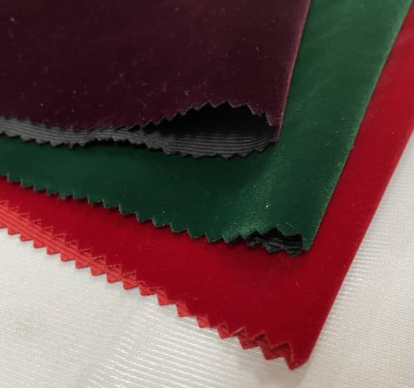

Black velour flocking material is widely used in high-end packaging and decorative applications. Its deep color, matte finish, and soft texture instantly elevate product presentation.

Luxury ring boxes, jewelry cases, cosmetic packaging, and premium gift boxes frequently use black velour flocking material to convey exclusivity and sophistication. Compared with smooth plastic or foam inserts, flocked interiors enhance perceived value and reinforce brand positioning.

Functional Benefits of Flocked Material in Industrial Use

Heat Insulation Performance of Flocked Material on Metal Products

Solid metal products conduct heat efficiently, which can pose safety risks in industrial and household applications. Flocked material acts as an insulating layer, reducing heat transfer and improving user safety.

For heaters, metal housings, and iron-based products, flocking helps prevent accidental burns and improves thermal comfort. This makes flocked material a practical solution for applications where both safety and usability are critical.

Safety Protection with Nylon Flocking Material

Nylon flocking material is known for its durability, resilience, and abrasion resistance. When applied to tools such as screwdrivers, handles, or razors, nylon flocking material provides a protective buffer between the user and the tool surface.

In cold climates, flocked tool handles prevent frost-related injuries by eliminating direct contact with cold metal. For sharp tools, flocking reduces the risk of cuts and enhances grip stability, improving overall safety.

Noise Reduction Using Flocked Material in Automotive Interiors

Flocked material plays an important role in automotive interiors by reducing noise and vibration. Applied to interior panels, storage compartments, and trim components, flocked surfaces absorb sound and minimize rattling.

Compared with bare plastic parts, flocked automotive components contribute to a quieter, more refined cabin environment. This acoustic benefit enhances driving comfort and supports higher-quality vehicle interiors.

Performance Advantages of Flocking in Apparel and Daily Products

Moisture Absorption in Flocking Clothes

Flocking clothes benefit from the moisture-absorbing properties of flock fibers. In apparel applications, flocked fabric can help manage sweat and improve comfort, particularly in activewear, loungewear, and winter garments.

The fiber structure increases surface area, allowing moisture to be absorbed and dispersed more effectively than smooth synthetic surfaces. This makes flocking clothing material suitable for functional and comfort-focused designs.

Anti-Slip Performance with Flocked Material

Flocked material naturally increases friction, making it an effective anti-slip solution. This property is widely used in gloves, footwear, tool handles, and household items.

Compared with smooth plastic or metal, flocked surfaces provide better grip without requiring additional textures or aggressive patterns. This balance of comfort and control is especially important for consumer products used daily.

Waterproof Solutions with Reverse Flocked Fabric

While flocking is often associated with softness, advanced techniques such as reverse flocking can also support waterproof performance. By applying flocking on the reverse side of fabrics, manufacturers can combine water resistance with comfort.

This approach is commonly used in outdoor clothing, protective apparel, and functional garments where waterproofing and skin comfort must coexist. Reverse flocked fabric offers practical performance without compromising wearability.

Types of Flocking Materials and Their Applications

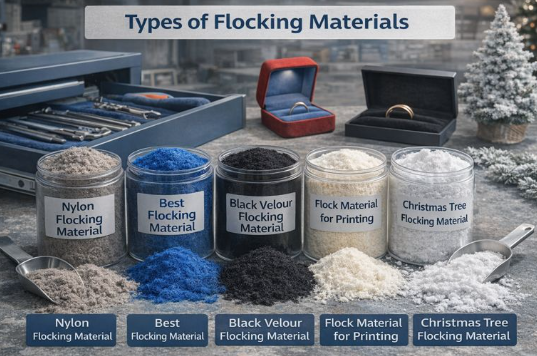

Choosing the Best Flocking Materials for Different Needs

Selecting the best flocking material depends on application requirements such as durability, softness, heat resistance, and environmental exposure. Nylon flocking material is preferred for industrial and high-wear applications, while rayon or polyester flock is often used for decorative and textile purposes.

Understanding end-use conditions helps determine the most suitable flock material and ensures long-term performance.

Flock Material for Printing and Decorative Surfaces

Flock material for printing combines tactile appeal with visual branding. Logos, patterns, and text can be printed alongside flocking to create distinctive, high-impact designs.

This technique is widely used in packaging, promotional materials, apparel graphics, and decorative surfaces, helping brands stand out through both look and feel.

Seasonal and Decorative Uses of Christmas Tree Flocking Material

Christmas tree flocking material is designed to create a realistic snow-like effect on artificial trees and holiday decorations. It enhances visual depth while maintaining strong adhesion and durability.

Beyond seasonal décor, this type of flocking material is also used in displays, window decorations, and themed installations, demonstrating the versatility of flocking technology.

Conclusion

Flocking technology offers a powerful combination of comfort, safety, functionality, and premium aesthetics that solid materials alone cannot achieve. From flocking clothes and apparel applications to industrial safety solutions and luxury packaging, flocked material continues to redefine surface performance across industries.

As a trusted flocking services supplier, Zhangs Flocking Materials provides professional electrostatic flocking solutions tailored to diverse application needs. By focusing on material selection, process control, and consistent quality, Zhangs helps clients achieve products that feel better, perform better, and stand out in competitive markets.