Flat flocking is a versatile and innovative technique that involves applying fine fibers to various surfaces using static electricity. Traditionally associated with fabric, flat flocking has evolved to be used on a variety of materials, offering countless possibilities in industries such as fashion, automotive, packaging, and home décor. In this article, we will explore what flat flocking is, how it works, its traditional applications, and its expanding use across multiple materials.

What is Flat Flocking?

-What is the Flat flocking meaning?

-Discuss the types of flocking material?

-Choosing the best flocking material for different applications

Traditional applications of flat flocking: flock print fabric

Expanding flat flocking beyond fabric: innovative uses on different materials

-PVC (Polyvinyl Chloride)

-Wood (Flat Wooden Surfaces)

-Cardboard

-PET (Polyethylene Terephthalate)

-Metal and Ceramics

Benefits of Flat Flocking Across Different Materials

Customizing with Custom Flock Printing

The Future of Flat Flocking

Conclusion

FAQs

What is Flat Flocking?

What is the Flat Flocking Meaning?

Flat flocking refers to a process where fine fibers, usually made of nylon, polyester, or cotton, are applied to a surface using static electricity. These fibers are electrostatically charged and then adhered to a surface coated with adhesive. The result is a smooth, velvet-like finish that adds texture and enhances the aesthetic quality of the material. Flat flocking creates not only visual appeal but also a distinct tactile experience, making it an ideal choice for many applications.

Discuss the Types of Flocking Material

The most common flocking material used in the process includes nylon, polyester, and rayon fibers. Each material offers unique qualities suited for specific applications:

1.Nylon flocking material is strong and durable, making it a popular choice for automotive and industrial applications. It offers a smooth, soft finish that is highly resistant to wear and tear.

2.Polyester flocking material is often used for applications where color retention and vibrancy are crucial, such as in fashion and home décor items.

3.Rayon flocking material provides a luxurious, shiny finish and is often used for high-end applications like decorative items and luxury packaging.

4.Cotton flocking material is soft and more absorbent, making it ideal for use in applications where comfort is a priority, such as in clothing and upholstery.

Choosing the Best Flocking Material for Different Applications

When selecting the best flocking material, it’s important to consider the specific requirements of the project. For example:

1.Durability: Materials like nylon are perfect for surfaces that will undergo heavy wear and tear, such as automotive parts.

2.Color Vibrancy: Polyester flocking is ideal for bright, eye-catching designs on fashion items or packaging.

3.Luxury Finish: Rayon flocking provides a smooth, shiny texture that is best suited for high-end or decorative applications.

4.Comfort: Cotton flocking is best used on textiles where softness and absorbency are essential.

Traditional Applications of Flat Flocking: Flock Print Fabric

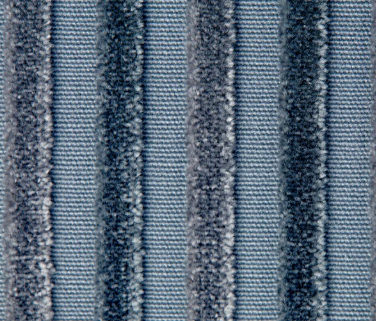

Flat flocking has long been used in the textile industry, primarily for creating textured and visually appealing fabric designs. Flock print fabric is a type of textile where fine fibers are applied to the surface of the fabric, creating a rich, velvety texture. This technique is widely used in fashion, upholstery, and home décor.

For instance:

1.Fashion: Flock print fabric has been used in clothing for centuries to create unique textures and patterns that elevate garments, making them stand out.

2.Upholstery: Flocking is also common in furniture, adding a luxurious and tactile feel to sofas, chairs, and curtains.

3.Home Décor: Flocked wallpapers and fabrics can transform a room, creating a high-end atmosphere with minimal effort.

Expanding Flat Flocking Beyond Fabric: Innovative Uses on Different Materials

PVC (Polyvinyl Chloride)

While flat flocking started with fabrics, it has now extended to materials such as PVC. PVC is used in a variety of industries, from footwear to automotive components. Flat flocking on PVC adds a soft, velvet-like finish while also enhancing its durability and visual appeal.

For example:

1.Footwear: Flocked PVC is used in creating fashionable footwear that not only looks appealing but also feels more comfortable.

2.Automotive: Flat flocking on car interiors, such as dashboards and trims, provides a smooth texture that is both aesthetically pleasing and functional.

Wood (Flat Wooden Surfaces)

Wooden surfaces, such as furniture, floors, and decorative items, can be treated with flat flocking to provide a soft, tactile feel. Flocking material applied to wood creates a unique texture that enhances its appearance while maintaining the natural elegance of the material. This technique is often used for luxury furniture and high-end wooden decorative pieces.

Cardboard

Flat flocking has also found a place in cardboard applications, where it adds texture and depth to packaging, greeting cards, and promotional items. By applying flocked fibers to cardboard, companies can elevate their product packaging to look more luxurious and engaging. This technique is often used in high-end packaging or limited edition products.

PET (Polyethylene Terephthalate)

PET is a common material used for bottles, containers, and various plastic items. Flat flocking on PET surfaces not only enhances the look and feel of the material but also adds to its tactile quality. For example, flocked plastic bottles or phone cases provide a smooth, velvety texture that is both pleasant to the touch and visually appealing.

Metal and Ceramics

Flocking is also used on metal and ceramic surfaces to create a velvety finish. This process is typically used in high-end décor items, such as decorative vases, jewelry, and even automotive parts. The flocking adds a luxurious touch, making otherwise cold and industrial materials appear soft and inviting.

Benefits of Flat Flocking Across Different Materials

Flat flocking offers numerous benefits when applied to a variety of materials:

Aesthetic Enhancement: It provides a luxurious, velvety texture that can transform the appearance of any material.

1.Durability: Flocked surfaces are often more resistant to scratches and wear, increasing the longevity of the product.

2.Tactile Appeal: Flat flocking creates a soft touch that enhances the user experience, whether it’s in clothing, furniture, or packaging.

3.Customization: Flat flocking offers endless possibilities for creating custom designs, patterns, and textures, making it perfect for tailored projects.

Customizing with Custom Flock Printing

Custom flock printing allows businesses and designers to create unique, personalized products using the flocking technique. This can be used in fashion, home décor, promotional items, and more. For example:

1.Fashion: Custom flock printing can create one-of-a-kind designs on clothing, making garments stand out.

2.Promotional Products: Businesses can use custom flock printing on promotional items like T-shirts, hats, and tote bags to create unique merchandise for their brand.

3.Home Décor: Custom flock printing can also be used to personalize items such as cushions, curtains, and bedspreads, adding a unique touch to home interiors.

The Future of Flat Flocking

The future of flat flocking looks promising as the technique continues to evolve with technological advancements. New flocking materials and methods are being developed to make the process more sustainable and efficient. Moreover, the growing demand for customization in consumer products ensures that flat flocking will continue to find new applications in a wide range of industries. As industries explore the benefits of eco-friendly and durable materials, flat flocking will likely play a key role in creating innovative products that are both functional and aesthetically pleasing.

Conclusion

Flat flocking is a versatile and innovative technique that has applications far beyond fabric. From PVC to wood, cardboard, PET, and ceramics, flat flocking enhances the appearance and feel of a variety of materials. With the added benefits of durability, customization, and aesthetic appeal, flat flocking is paving the way for new possibilities in industries such as fashion, automotive, packaging, and home décor. As the technique continues to evolve, the future of flat flocking holds even greater potential for innovation and creativity.

FAQs

What Is Flocking Used For?

Flocking is used to add texture and visual appeal to various materials, including fabric, wood, plastic, and paper. It is commonly used in fashion, automotive interiors, packaging, and home décor to create a soft, velvet-like finish.

What Is Flocking Material?

Flocking material consists of fine fibers, usually made of nylon, polyester, cotton, or rayon, that are applied to a surface using static electricity. These fibers create a soft, textured finish and can be used on a wide range of surfaces for decorative or functional purposes.

Is Flocking Fiber Dangerous?

Flocking fibers themselves are generally not dangerous. However, inhaling large amounts of fine fibers during the flocking process can pose a risk to respiratory health. Proper ventilation and safety precautions should be taken to avoid inhalation.